General description:

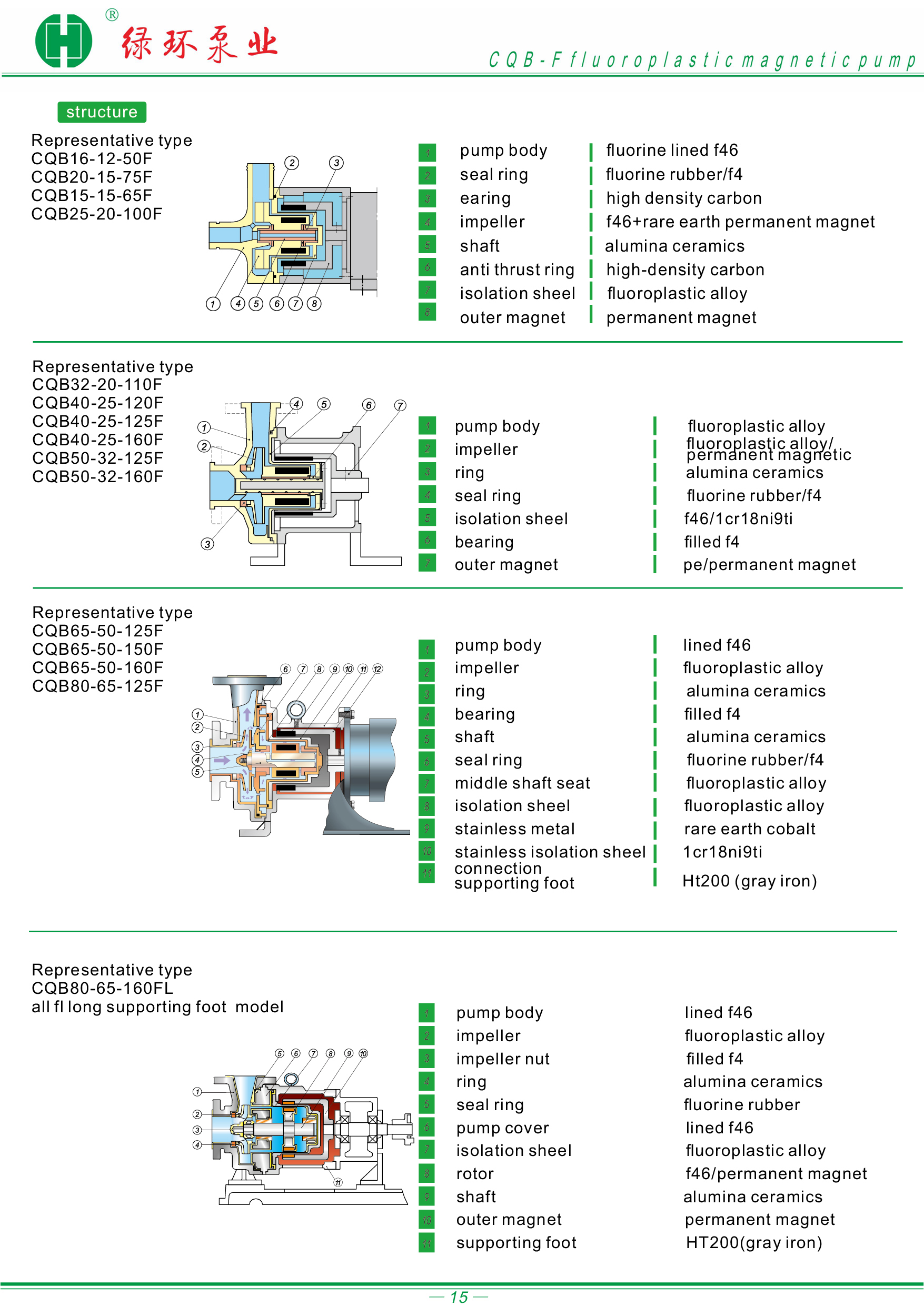

The traditional structure has many disadvantages, such as the anti-thrust ring is non-replaceable, the bearing is easy to wear, the axial force is unbalanced and easy -cavitation.

Pump cover: 1-2 carbon fiber or graphite bearings are arranged in the bearing hole cover, and the interference pressing assembly type is adopted.this type of assembly will cause the bearing inner hole deformation and roundedness, which will cause the pump to fail to operate or the bearing ablation in serious cases, and lower the bearing wear resistance.

Anti-thrust ring: Using carbide or silicon carbide through the hot mount mounted on the impeller and rotor, affected by the temperature is easy to fall off, and can not be replaced separately, once damaged, you have to replace the entire impeller or rotor together with high cost.

Pump shaft:The ordinary 304 pump shaft and the graphite bearing is directly grinding and supporting the palm, because 304 is not wear-resistant, easy to wear. Some manufacturers use shaft and SiC sleeve, but 304 and SiC expansion coefficient is different, greatly affected by temperature, easy to crack SiC.

Inner rotor: Single set of magnetic steel design, large outer diameter, large magnetic loss

Outer rotor: Single set magnetic steel design, large outer diameter, large magnetic loss, and the external magnetic barrel is small, serious magnetic leakage.

Special structure design: Cqb type without self-balancing design, just depend on anti-thrust ring and bearing friction barrier limit.